Our client deals with a machines specified for crushing hard rocks, which contains a set of parts with:

1.High consumption and periodic replacement rate

2.Long and complex supply chains for procuring the spare parts

3.A high cost of storing these parts.

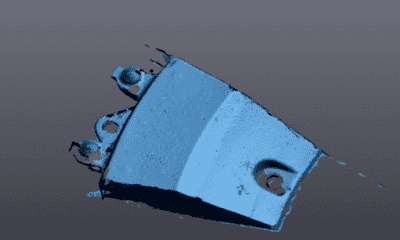

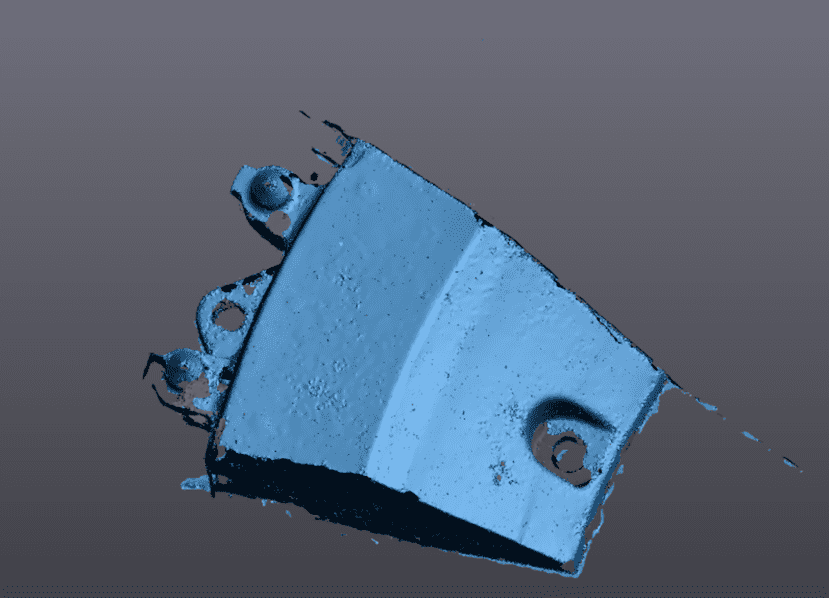

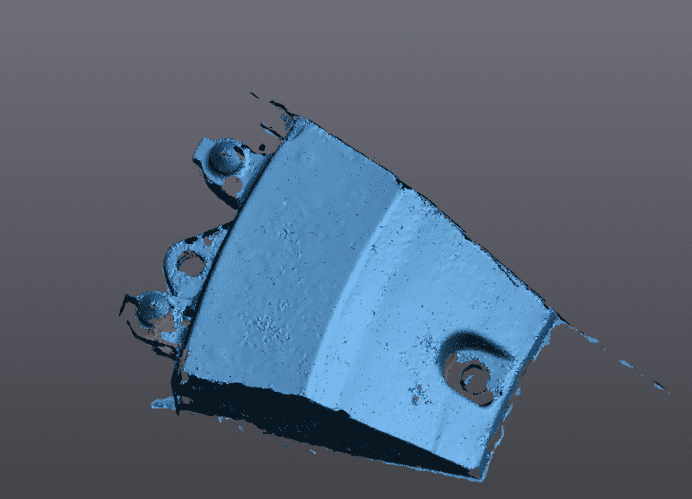

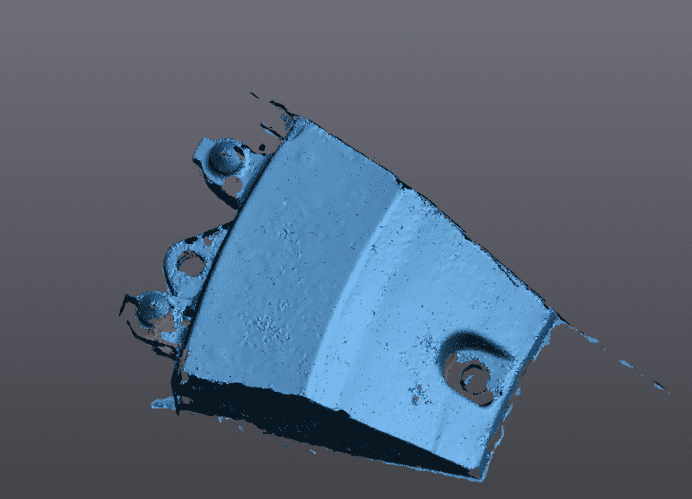

At first, Namthaja reverse-engineered the spare parts by using laser scanning devices, to take the identical measurements.

Then we 3D printed several models to test the fit on the crushing machine to ensure the quality of the measurements.

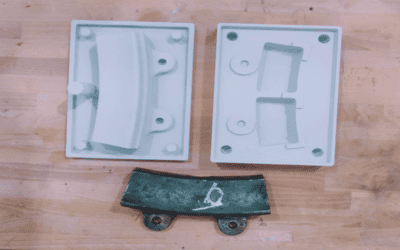

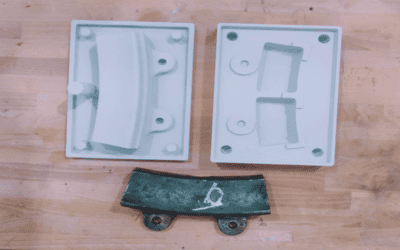

Next, the molding patterns were 3D printed.

Thereafter the molds were manufactured to be locally forged in a foundry, according to the specified metal.

Many different spare parts were produced in this project, and in the desired quantities.

To finally complete the:

Localization of supply chains

Releasing the inventory liquidity

Reduction of the procurement & lead time

Our client deals with a machines specified for crushing hard rocks, which contains a set of parts with:

1.High consumption and periodic replacement rate

2.Long and complex supply chains for procuring the spare parts

3.A high cost of storing these parts.

At first, Namthaja reverse-engineered the spare parts by using laser scanning devices, to take the identical measurements

Then we 3D printed several models to test the fit on the crushing machine to ensure the quality of the measurements.

Next, the molding patterns were 3D printed.

Thereafter the molds were manufactured to be locally forged in a foundry, according to the specified metal.

Many different spare parts were produced in this project, and in the desired quantities.

To finally complete the:

Localization of supply chains

Releasing the inventory liquidity

Reduction of the procurement & lead time