This work is better described as a contributory manufacturing relationship, rather than a single project.

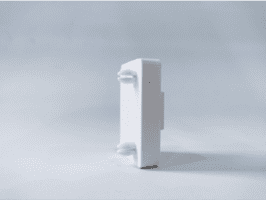

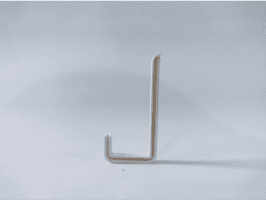

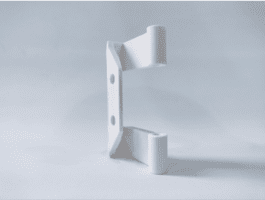

As per our client’s production process that adapts to our industrial services in an integrated manner, relying on 3D printing to provide assembly parts, hinges, and many other parts.

These parts are manufactured in large quantities within a few days, sometimes hours, and without any capital costs such as molds. Which allows incomparable manufacturing flexibility and freedom to make alterations to the designs whenever needed.

This contributory manufacturing extended to include different products, and to meet the needs of varying quantities, purposes, and solutions provided.

Quantity variance:

8000 pieces

3000 pieces

3000 pieces

1000 pieces

160 Pieces

Limited quantities for prototype….

and others

Needs variance:

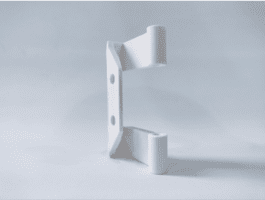

To assemble the parts

To solve a defect problem

To solve a frequent fracture problem

To be installed on a base or surface…. and others

The production process included:

- The Design,

- Development at Namthaja,

- On-site Tests,

- Final Production.